HOW I DO IT

TRANSPARENCY & TRACEABILITY

I run Teddy Locks on my own.

I design and develop all of the styles from my home in Oxted, Surrey and ship them directly from here to you.

BUT - I wouldn't be able to produce these incredible socks without the help of some amazing small businesses, and their machinery.

Due to manufacturing limitations (and an absense of technology) in the UK, Teddy Locks are made entirely within North Carolina.

In doing so, they have an impossibly small footprint - and travel just 200 miles in production!

I am really proud of this achievement and am proud to be fully transparent about the process.

FIBER MILL

Plastic bottles are collected from the east coast of the USA.

They're sorted, chopped up & melted by UNIFI in North Carolina.

Then made into high-performance textile fibers for Teddy Locks.

Together, we've transformed more than 28,000 plastic bottles

& saved more than 3,000lbs of trash from landfill!

SPINNING MILL

Our recycled fibers are spun into our specially crafted,

luxuriously soft yarns - without the use of chemicals or water.

I use five specially engineered yarns in all Teddy Locks socks.

DYE HOUSE

Spartan Dyers, a local, family run business based near Charlotte,

dye our custom colors - including our Teddy Locks yellow.

From fiber to finishing, Teddy Locks socks travel less than 200miles!

KNITTING MILL

I knit all Teddy Locks socks at Robinwood Enterprises

- a family run operation dedicated to helping the community.

Here, green certified machines knit each of our socks as a single piece.

So that trimmings from color changes are the only waste generated.

We are working with Robinwood on a recycling program

that benefits all of the brands using the mill.

They are 100% American Made,

FINISHING

All Teddy Locks socks are washed without detergents or chemicals.

There's no drying process - instead I have them boarded using only steam.

Once pressed, each sock is inspected by hand.

and the World's Most Sustainable Socks!

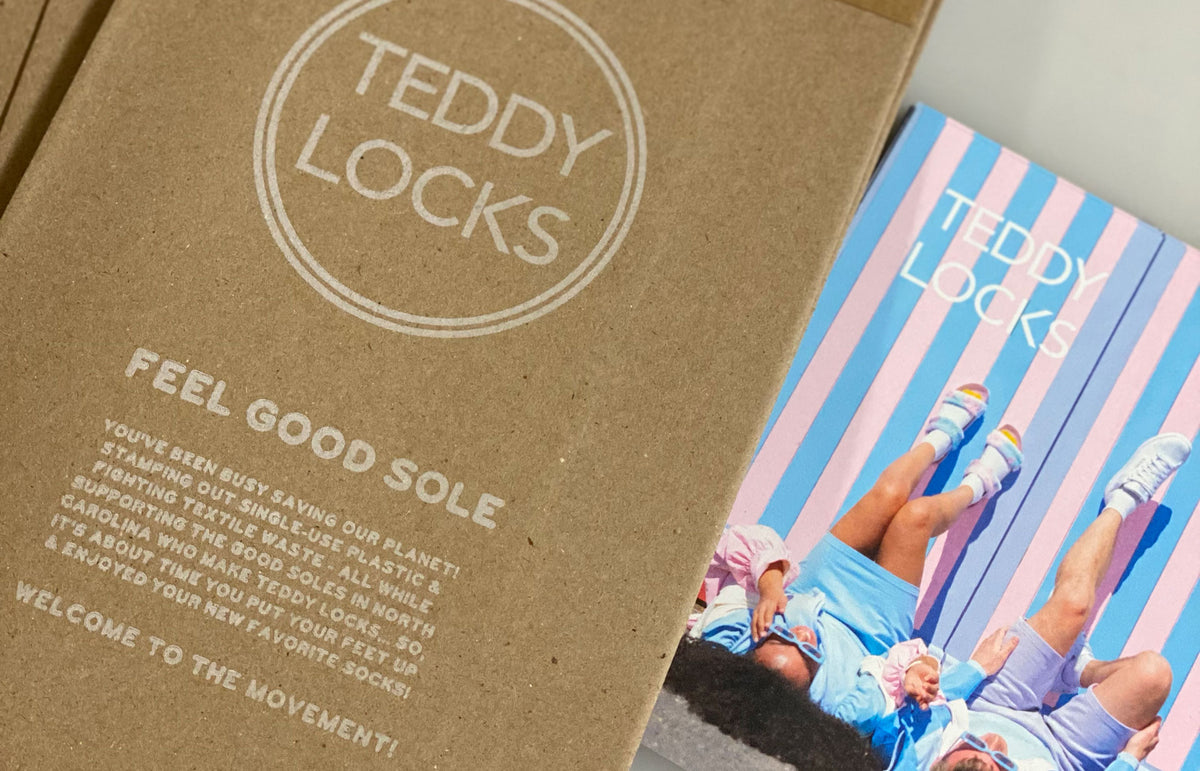

PACKAGING

All of our packaging,

from the stickers & tissue paper to the mailers & labels,

are 100% recyclable, & made in the USA from 100% recycled paper.